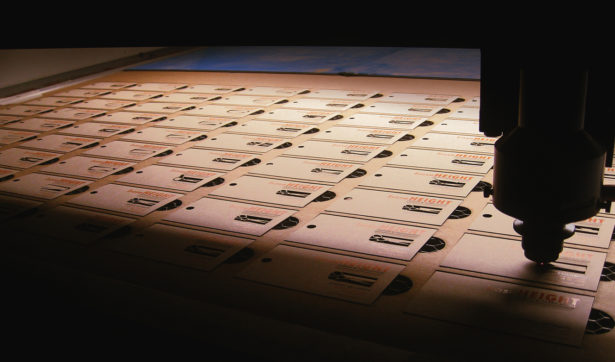

Portfolio / Baseheight Business Card

Client:

BaseheightMaterial:

PaperTechniques:

Laser CuttingType:

Graphic Design

For our own business cards we knew we wanted to incorporate laser cutting to quickly communicate the type of work we do in a memorable way. We selected a variety of simple hand tools as the laser cut elements of the card to convey the idea of fabrication, and to serve as a nice contrast to the digital fabrication techniques used to produce such intricate elements. We decided to start with a pre-printed card in order to keep the production time down. That way as information was changed or updated, we could print new cards prior to laser cutting. The standard-sized cards could then be popped into a jig and the production files used for the laser cutting could be re-used without editing.

While we have produced fully laser-cut and engraved cards in the past, the time needed to produce them often ends up being cost-prohibitive for a business card. Thus, our own cards could serve as an example of the balance between intricacy and efficiency that is a key conversation that should happen at the start of a project.